Oxygen Equipment

Use in General Aviation Operations

Oxygen Equipment Use in General Aviation Operations A basic knowledge of oxygen equipment can be critical whether you are flying a commercial, commuter, or a general aviation aircraft. This equipment is the first line of defense against the potentially lethal effects of hypoxia and carbon monoxide poisoning. It is the responsibility of the pilot that all aboard the aircraft, crew-members and passengers, know how to use this life-saving equipment safely and efficiently.

General Precautions

The [information in this article] describes operational precautions to use with all types of oxygen systems. The basic principles and practices include:

- Keep your equipment clean. The interaction of oil-based products and oxygen creates a fire hazard. Additionally, oil attracts dirt particles, and these dirt particles can contaminate storage containers, regulators, masks, and valves. For cleaning instructions, check with the manufacturer’s guide.

- Protect your oxygen mask from direct sunlight and dust. Store in proper containers.

- Inspect oxygen storage containers. Make sure that they are securely fastened in the aircraft, as turbulence or abrupt changes in attitude can cause them to come loose. Proper inspections are important, so your oxygen equipment should be inspected regularly at an authorized Federal Aviation Administration inspection station.

- No smoking! Although oxygen itself is not flammable, it can cause other materials to ignite more easily and will make existing fires burn hotter and faster. Do not allow anyone to smoke around oxygen equipment that is being used. Likewise, no one should smoke around oxygen equipment that is being recharged. Ensure that the aircraft is properly grounded before loading oxygen.

Mix and match components with caution. When inter-changing oxygen systems components, ensure compatibility of the components – storage containers, regulators, and masks.

Basic Components

There are three components to most oxygen systems, whether they are portable or installed systems:

- A storage system (containers)

- A delivery system

- Mask or nasal cannula

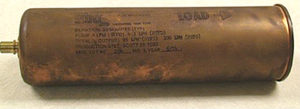

Storage Systems

Oxygen can be stored in the aircraft as a gas, liquid, or a solid.

Gaseous aviator’s breathing oxygen (ABO)

Storing oxygen as a gas has the major advantage of being more economical. It can be stored in high-pressure (1800-2200 psi) containers or low-pressure (400-450 psi) containers.

Storing oxygen as a gas has the major advantage of being more economical. It can be stored in high-pressure (1800-2200 psi) containers or low-pressure (400-450 psi) containers.

The major disadvantage is the weight and bulk of the storage containers, which may become an issue in smaller aircraft. Aviator’s oxygen must meet certain standards to ensure that it is safe to be taken to altitude.

Only aviator- grade breathing oxygen meets this specification. Neither medical-grade nor industrial-grade oxygen is safe to substitute because they do not meet the same stringent standards as ABO.

Liquid aviators breathing oxygen (LOX)

Oxygen can be serviced to the aircraft in a liquid state. The advantage of LOX is that it has a nine hundred-to-one expansion ratio. In other words, one liter of LOX will expand into 900 gaseous liters of ABO. This provides a three-to-one space and a five-to-one weight savings over gaseous ABO.

The major disadvantages are that LOX is stored at its critical temperature of minus 197º F and its volatile nature when it comes in contact with petroleum products. If LOX comes in contact with exposed skin, severe frostbite may occur.

Sodium chlorate candles (solid-state oxygen)

Sodium chlorate is a chemical that, when heated to 350º F, will thermally decompose and release oxygen. Sodium chlorate candles have the advantage of saving weight and space over ABO because they provide a six hundred-to-one expansion ratio.

Sodium chlorate is a chemical that, when heated to 350º F, will thermally decompose and release oxygen. Sodium chlorate candles have the advantage of saving weight and space over ABO because they provide a six hundred-to-one expansion ratio.

The major disadvantage is that once the chemical reaction starts (the candle is activated), it can’t be stopped easily. Additionally, the candle produces a great deal of heat and precautions must be taken to avoid a fire hazard.

Molecular sieve oxygen generators (MSOG). The air we breathe contains 21% oxygen and the remainder is nitrogen and inert gases that play no major role in respiration. MSOGs take ambient air and separate oxygen from the nitrogen and inert gases. The separated oxygen is concentrated and used to supply the aircraft.

The military has used this system for many years, as well as medical patients who need a portable oxygen system. Civil aviation hasn’t embraced MSOG, but it may become more common in future aircraft.

Oxygen Delivery Systems

Continuous flow

This system delivers a continuous flow of oxygen from the storage container. It is a very economical system in that it doesn’t need complicated masks or regulators to function. But it is also very wasteful—the oxygen flow is constant whether you’re inhaling, exhaling, or pausing in between breaths. This system is typically used at 28,000 feet and lower.

Diluter demand

The diluter demand system is designed to compensate for the shortcomings of the continuous flow system. It gives the user oxygen on-demand (during inhalation) and stops the flow when the demand ceases (during exhalation). This helps conserve oxygen. Additionally, the incoming oxygen is diluted with cabin air and provides the proper percentage of oxygen, depending on the altitude. This system is typically used at altitudes up to 40,000 feet.

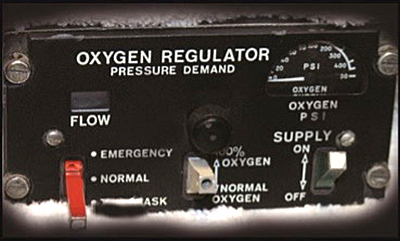

Pressure demand

This system provides oxygen under positive pressure. Positive pressure is a forceful oxygen flow that slightly over-inflates the lungs. This will, in a sense, pressurize the lungs to a lower altitude, thus allowing you to fly at altitudes above 40,000 feet, where 100% oxygen without positive pressure is insufficient.

Oxygen Masks and Cannulas

When considering an oxygen mask, you must ensure that the mask you are using is compatible with the delivery system you are using.

Nasal cannulas

These are continuous-flow devices and offer the advantage of personal comfort.

They are restricted by federal aviation regulations to 18,000 feet service altitude because of the risk of reducing blood oxygen saturation levels if one breathes through the mouth or talks too much.

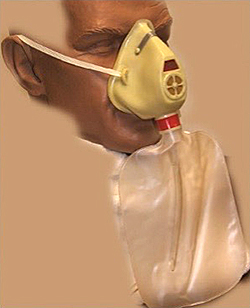

Oral-nasal re-breather

This mask is the most common and the least expensive. It is also the simplest to use; it has an external plastic rebreather bag that inflates every time you exhale. The purpose of the rebreather bag is to store exhaled air, so that it may be mixed with 100% oxygen from the system. These masks supply adequate oxygen to keep the user physiologically safe up to 25,000 feet.

Quick-don mask

These masks must have the capability to be donned with one hand in 5 seconds or less, while accommodating prescription glasses. Quick-don masks are typically suspended or stored to permit quick and unimpeded access by flight deck crew. These masks are typically rated to altitudes up to 40,000 feet.

Airline drop-down units (Dixie cup)

The continuous flow, phase-dilution (or phase-sequential) mask looks similar to a general aviation re-breather mask. However, the masks function differently and the phase dilution mask allows the user to go to higher altitudes.

This mask uses an external reservoir bag and a series of one-valves working in sequence to allow a mixture of 100% oxygen and cabin air into the mask. When activated by pulling down on a suspended mask, oxygen from a supply source flows continuously into the reservoir bag.

During inhalation, a one-way valve allows the flow of oxygen from the reservoir bag into the lungs. If the reservoir bag empties before inhalation is complete, a second one-way valve on the mask face piece opens to permit the flow of cabin air into the mask, allowing the user to take a full breath.

If the user is breathing rapidly the reservoir bag will appear to not fully inflate. Expired air is vented out of the mask into the cabin via a one-way exhalation valve; expired air is not returned to the reservoir bag. This mask can be safely used at emergency altitudes up to 40,000 feet.

The PRICE Check

Prior to every flight, the pilot should perform the “PRICE” check on the oxygen equipment. The acronym PRICE is a checklist memory-jogger to help pilots and crewmembers inspect oxygen equipment.

• PRESSURE – Ensure that there is enough oxygen pressure and quantity to complete the flight.

• REGULATOR – Inspect the oxygen regulator for proper function. If you are using a continuous-flow system, ensure that the outlet assembly and plug-in coupling are compatible.

![]() • INDICATOR – Most oxygen delivery systems indicate oxygen flow by use of flow indicators. Flow indicators may be located on the regulator or within the oxygen delivery tube. Don the mask and check the flow indicator to ensure a steady flow of oxygen.

• INDICATOR – Most oxygen delivery systems indicate oxygen flow by use of flow indicators. Flow indicators may be located on the regulator or within the oxygen delivery tube. Don the mask and check the flow indicator to ensure a steady flow of oxygen.

• CONNECTIONS – Ensure that all connections are secured. This includes oxygen lines, plug-in coupling, and the mask.

• EMERGENCY – Have oxygen equipment in the aircraft ready to use for emergencies that require oxygen (hypoxia, smoke and fumes, rapid decompressions/ decompression sickness). This step should include briefing passengers on the location of oxygen and its proper use.

Be Aware

From a safety-of-flight standpoint, oxygen equipment is an issue that should concern all pilots. Know the equipment you have on board, know when to use it, and most importantly, know its limitations. It’s your key to a safe and enjoyable flight.

Federal Aviation Regulations and Oxygen Use

(Title 14 of the Code of Federal Regulations)

Part 91

General Operating and Flight Rules

91.211 Supplemental oxygen.

(a) General. No person may operate a civil aircraft of U.S. registry—

1) At cabin pressure altitudes above 12,500 feet (MSL) up to and including 14,000 feet (MSL) unless the required minimum flight crew is provided with and uses supplemental oxygen for that part of the flight at those altitudes that is of more than 30 minutes duration;

(2) At cabin pressure altitudes above 14,000 feet (MSL) unless the required minimum flight crew is provided with and uses supplemental oxygen during the entire flight time at those altitudes; and

(3) At cabin pressure altitudes above 15,000 feet (MSL) unless each occupant of the aircraft is provided with supplemental oxygen.

(b) Pressurized cabin aircraft. (1) No person may operate a civil aircraft of U.S. registry with a pressurized cabin—

(i) At flight altitudes above flight level 250 unless at least a 10-minute supply of supplemental oxygen, in addition to any oxygen required to satisfy paragraph (a) of this section, is available for each occupant of the aircraft for use in the event that a descent is necessitated by loss of cabin pressurization; and

(ii) At flight altitudes above flight level 350 unless one pilot at the controls of the airplane is wearing and using an oxygen mask that is secured and sealed and that either supplies oxygen at all times or automatically supplies oxygen whenever the cabin pressure altitude of the airplane exceeds 14,000 feet (MSL), except that the one pilot need not wear and use an oxygen mask while at or below flight level 410 if there are two pilots at the controls and each pilot has a quick-donning type of oxygen mask that can be placed on the face with one hand from the ready position within 5 seconds, supplying oxygen and properly secured and sealed.

(2) Notwithstanding paragraph (b)(1)(ii) of this section, if for any reason at any time it is necessary for one pilot to leave the controls of the aircraft when operating at flight altitudes above flight level 350, the remaining pilot at the controls shall put on and use an oxygen mask until the other pilot has returned to that crewmember’s station.

PART 135 OPERATING REQUIREMENTS:

Commuter and On Demand Operations and

Rules Governing Persons On Board Such Aircraft

Sec. 135.89 Pilot requirements: Use of Oxygen.

(a) Unpressurized aircraft. Each pilot of an unpressurized aircraft shall use oxygen continuously when flying—

(1) At altitudes above 10,000 feet through 12,000 feet MSL for that part of the flight at those altitudes that is of more than 30 minutes duration; and

(2) Above 12,000 feet MSL. (b) Pressurized aircraft. (1) Whenever a pressurized aircraft is operated with the cabin pressure altitude more than 10,000 feet MSL, each pilot shall comply with paragraph (a) of this section.

(2) Whenever a pressurized aircraft is operated at altitudes above 25,000 feet through 35,000 feet MSL, unless each pilot has an approved quick-donning type oxygen mask–

(i) At least one pilot at the controls shall wear, secured and sealed, an oxygen mask that either supplies oxygen at all times or automatically supplies oxygen whenever the cabin pressure altitude exceeds 12,000 feet MSL; and

(ii) During that flight, each other pilot on flight deck duty shall have an oxygen mask, connected to an oxygen supply, located so as to allow immediate placing of the mask on the pilot’s face sealed and secured for use.

(3) Whenever a pressurized aircraft is operated at altitudes above 35,000 feet MSL, at least one pilot at the controls shall wear, secured and sealed, an oxygen mask required by paragraph(b)(2)(i) of this section.

(4) If one pilot leaves a pilot duty station of an aircraft when operating at altitudes above 25,000 feet MSL, the remaining pilot at the controls shall put on and use an approved oxygen mask until the other pilot returns to the pilot duty station of the aircraft.

Physiological Training Classes for Pilots

CAMI offers physiological training for civil aviation pilots, FAA flight crews, and FAA aviation medical examiners at our facilities in Oklahoma City, Oklahoma including practical demonstrations of rapid decompression in a hypobaric (altitude) chamber or Portable Reduced Oxygen Training Enclosure (PROTE). Visit this FAA website to sign up for this training: https://faa.gov/go/aerophys

Provided by Aerospace Medical Education Division, AAM-400.

Reprinted with permission from FAA Safety Briefing. Visit the Flight Safety Briefing website: https://www.faa.gov/news/safety_briefing/.