Not Just Your Average Mechanic

Aviation Maintenance Technicians Have the Most Important Job In Aviation

By Jennifer Caron

What comes to mind when you think of an aviation mechanic? Do you picture a grease-stained guy in grimy overalls, cleaning his hands with a rag, as he critically walks around your aircraft looking for any problems he can find to justify the steep bill he’s going to hit you with before you can get your bird back in the air? Or do you picture a highly-skilled, highly-trained, and well-educated aviation professional whose mission is to find and prevent problems before they happen and to whom you must trust your life?

Although pilots receive a lot of the glory, aviation safety is not just about an ace in the cockpit. It’s also about a properly maintained and airworthy airplane that is as dependent on the technicians who service and repair it as it is on the pilots who operate it. I will argue that pilots need mechanics more than mechanics need pilots.

Aviation maintenance technicians (AMTs) are the unsung, often forgotten men and women where “everybody only knows your name” when something breaks or goes wrong. It’s hard work — behind the scenes, under the cowling in the drafty hangar with the rattling doors and dangerous chemicals, making life or death decisions under mounds of paperwork and pressure to meet the standards and the deadlines, and balancing the tensions between safety and cost to keep the customer happy.

So when you see mighty aircraft, as they mark their way through the air, the grease-stained man with the wrench in his hand is the man who put them there … — A Tribute to the Forgotten Mechanic, Author Unknown

From Pulling Panels to Signature Authorizations

AMTs are not just your average run-of-the-mill mechanics. They are held to the highest standard of safety. AMTs start with a rigorous FAA training and certification process, and they don’t stop learning until they retire. Their work is detailed, regulated, and stringent. They use a laptop as much as they use a wrench. Even routine tasks are step-by-step, and to the letter with secondary systems and redundancies in place, so there’s no room for cutting corners or making mistakes. From pulling off panels, to diagnosing complex flight management systems, to signing off on inspections; these skills can take years of service, training, and education to develop and master. It takes a great deal of work, growth, and dedication to be an AMT. AMTs perform a vital service that is not only critical to safety but also to the economy.

Fusing it All Together — It’s Riveting

“My dad was in the Air Force as a crew chief on the B-36 [Peacemaker],” says Alby Redick, President of Aviation Classics, Ltd. in Reno, Nev. “I have always loved flying and working on aircraft. I was just born into it.”

Ask any AMT, and they can tell you what inspired them to pursue their career in aviation. For some, it was their natural ability to fix things, taking them apart and putting them back together again — the right way. Still others, who could tell aircraft types just by the sound they made, were always curious to learn the principles of flight and the forces that keep the metal birds in the sky. AMTs eat, breathe, and sleep airplanes, and they’re never afraid to get their hands dirty.

“I was an apprentice mechanic when I was in high school,” says Guy Minor, former AMT and current aviation safety inspector and FAA Safety Team airworthiness program manager. “I remember one day I’m lying under the belly of a Champ cleaning oil off the airplane with a dry rag in one hand and a rag soaked in solvent in the other, doing ‘wax on, wax off,’ while the oil and solvent are just running down my arms. I looked up and thought, ‘you know, I would never do this on a car.’ Airplanes are magic; they’re special; they’re alive.”

Our first aviation mechanic, Charles E. Taylor, who designed and built the engine for the Wright Brothers’ first successful aircraft, knew from an early age that he was a born problem solver and mechanically inclined. That’s lucky for the Wrights because there were no regulations, manuals, or manufacturer instructions to follow in those days. Charlie had to diagnose and troubleshoot on the fly, making repairs as problems occurred.

All of that would change. In 1927, the newly created Aeronautics Branch of the Department of Commerce issued the first federal aircraft mechanic license, which required mechanics who repaired air commerce aircraft to secure either an engine or an airplane mechanic’s license, or both. The Branch also issued the first air commerce regulations and the first airworthiness type certificate for the Buhl Airster CA-3, a three-place open biplane.

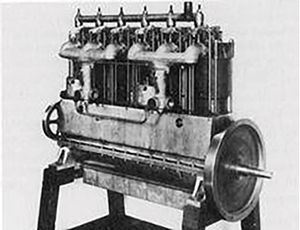

A late-model Wright “6–60” six-cylinder engine, circa 1915, built by Charles Taylor. This was one of the last engines produced by the Wright Company. Photo courtesy of wright-brothers.org.

A Day at the Beech

Since then, aviation maintenance techniques, technology, and safety have advanced and evolved. “Not much has changed as far as engines go. Nearly everything in the internal combustion line is still old school technology,” says Ken Kelley, former AMT and current aviation safety inspector and FAA Safety Team airworthiness program manager. When it comes to repairing a Beechcraft, Cessna, or Piper, those airplanes are still straight out of the 1970s or earlier. “They might have real fancy avionics packages, or an electronic ignition or fuel injection, but the engine designs are still the same — right out of WWII and haven’t changed much,” says Minor.

In the not-so-distant past, analog and mechanical systems, affectionately known as “steam gauges,” were the norm. Using push-to-test problem solving, mechanics would gauge when a component was close to the limit and replace parts before they wore out. They relied on their senses as well to diagnose and troubleshoot. “Your senses tell you a lot about the airplane. You can smell things when they’re hot or if an engine is worn out or low in oil, it has a certain smell,” Minor explains.

These sensory techniques have not changed; they’re just another wrench in the toolbox for AMTs who have to be up to speed on all types of aircraft, from legacy platforms on aging aircraft to the latest bells and whistles in glass cockpit technology.

Many of today’s airplanes are run by computers, and mechanics are retrofitting older aircraft with electronic instruments. Nowadays, AMTs use a laptop to diagnose complex navigational databases or flight management systems. Still, it’s also vital for AMTs to rely on their core safety culture skills.

“I’ve been doing this a long time, but I’m still learning, and I still have to check myself. Are there habits and practices that have crept into the work that could leave you complacent? For example, many annuals are performed on the same aircraft by the same person year after year. Perform every third 100-hour inspection by a different person to get a different perspective. Don’t get stuck in a rut, be curious, avoid disruptions, and never assume. Ask questions and verify.” — Michael Dunkley, 2021 National Aviation Technician of the Year

New technology and innovation have propelled safety and progress. “The major advancements are tied to newer technology in the accessory side of things,” explains Kelley. “We have electronic ignition coming up more and more and better electronic engine monitoring systems that allow us to spot problems before they morph into major issues. FADEC, full authority digital engine control, shows up in the newer aircraft built today. More advances with fuel, ignition, and air and power management have made the older engines more economical to operate and more consistent with power output,” he says.

“With regard to preventive maintenance,” says Kelley, “new technology, like advanced monitoring systems for exhaust gas temperatures (EGT), RPMs, oil temperatures, and cylinder temperatures, has allowed us to see issues in performance and instrumentation so that we can address a problem before it becomes a catastrophic failure. Identifying issues and fixing them before they turn into major problems saves us money, reduces the aircraft downtime, and helps to get an engine to TBO [time between overhauls] without costly failures.”

Torquing Bolts and Typing on Keyboards

“Of course, the computer and internet have made the largest impact in the hangar,” says Redick. “We now have computer terminals set up around the shop for our guys: no more paper slips or paper tracking. We have computerized maintenance and parts manuals, technical publications, inventory, logbook entries, and FAA Form 337s, to name a few,” he explains.

“When I started back in 1983, all the data was stored on microfiche and in paper books. It may as well have been carved into stone tablets when we compare that to what we have now. AD [Airworthiness Directive] and Service Bulletin research takes a fraction of the time to complete now versus 20 to 40 years ago. Improved tooling like affordable, flexible borescopes and digital micrometers make the job of inspecting hard-to-see places much easier to accomplish without any real disassembly of components. Measuring the wear on parts using optical devices has improved, and electronic measuring equipment has made our results much more accurate,” says Kelley, who owns and maintains a Cessna 172N.

An AMT is a jack of all trades and every day in the hangar or on the flight line presents a new challenge and a new opportunity to develop skills while crawling over different aircraft. “It really helps when your mechanics can work on diverse projects, as opposed to working a narrow scope of services,” says Redick, who credits the success of his shop on the diversity of services that they offer.

The hangar at Aviation Classics, Ltd. in Reno, Nev. Photo courtesy of Aviation Classics, Ltd.

Math — It’s Not Just for Wrenches

The maintenance industry is evolving and diverse, yet at the same time, baby boomer mechanics are retiring in large numbers. We’ve got a shortage today that’s projected to shrink the workforce of tomorrow. Add to that a reduction of students entering AMT schools, coupled with graduates taking jobs in other higher-paying fields such as robotics and hydraulics, and you’re looking at a shortfall that’s affecting MROs and mom and pop shops alike. AMTs need to share their passion and knowledge with the next generation and promote education in science, technology, engineering, and math (STEM) to help ensure a pipeline of qualified AMTs for the future.

“AMTs should assist owners and encourage owner-assisted annuals. Don’t take your knowledge to the grave; pass it on to the next generation.” — Dennis Wolter, 2020 National Aviation Technician of the Year

“Most kids want a clean job and don’t seem to want to have to get their hands dirty, but fortunately, there are some that still love doing so. Tech schools are a good start; STEM programs are great,” says Riddick, who believes it all comes down to work ethic. “If a young person loves electronics, encourage them to become an avionics installer, bench technician, or a mechanic trainee.”

The demand to fill these STEM-related jobs exists right now, and the need is only growing. This year, the FAA awarded $5 million in aviation workforce grants to train the next generation of AMTs.

“In the old days, the diesel and car mechanics had a much better paying job,” says Riddick. “The upside to the shortage and increased demand in our industry is that wages have finally come up to a more livable wage.”

Snap-on Tools of the Future

We’re looking at a future of new-generation aircraft, aircraft engines, propellers, and appliances manufactured using advanced materials, processes, and equipment, calling for more advanced maintenance techniques.

If you’ve ever had an MRI or a CT scan at the doctor, then you’ve got an idea of how Nondestructive Inspection and Testing work. NDI and NDT are similar techniques using X-Rays or ultrasonic equipment to inspect and verify the condition of aircraft, engines, propellers, and other aviation components without causing any damage. It’s accurate, cost-effective, and preventive and allows technicians to get a look inside before replacing or repairing components.

FedEx uses drones to inspect exterior surfaces on aircraft in their fleet, which increases data collection and quality, improves employee safety, takes inspection times down from three hours to 20 minutes, and allows AMTs to focus on more specialized jobs.

Additive Manufacturing (AM) technology is a new process to join materials to make aircraft parts using data from computer-generated 3-D models. In that same vein, AI, artificial intelligence, is now being used in predictive maintenance.

Kelley, an avid Star Trek fan, is excited for the future of aviation maintenance. “When you add in the advancements in composite structures and metal spray to repair fan blades and internal engine components, it’s easy to see that in another decade, the aviation environment will be much different than what it was a short time ago. Now, if I could just remember where I put the dilithium crystals and the plasma couplers!”

Jennifer Caron is FAA Safety Briefing’s copy editor and quality assurance lead. She is a certified technical writer-editor in the FAA’s Flight Standards Service.

Reprinted with permission from FAA Safety Briefing. Visit the Flight Safety Briefing website: https://www.faa.gov/news/safety_briefing/.